Elevator Jack Units - Elevator Jacks

Hydraulic Elevator Jacks

General Information

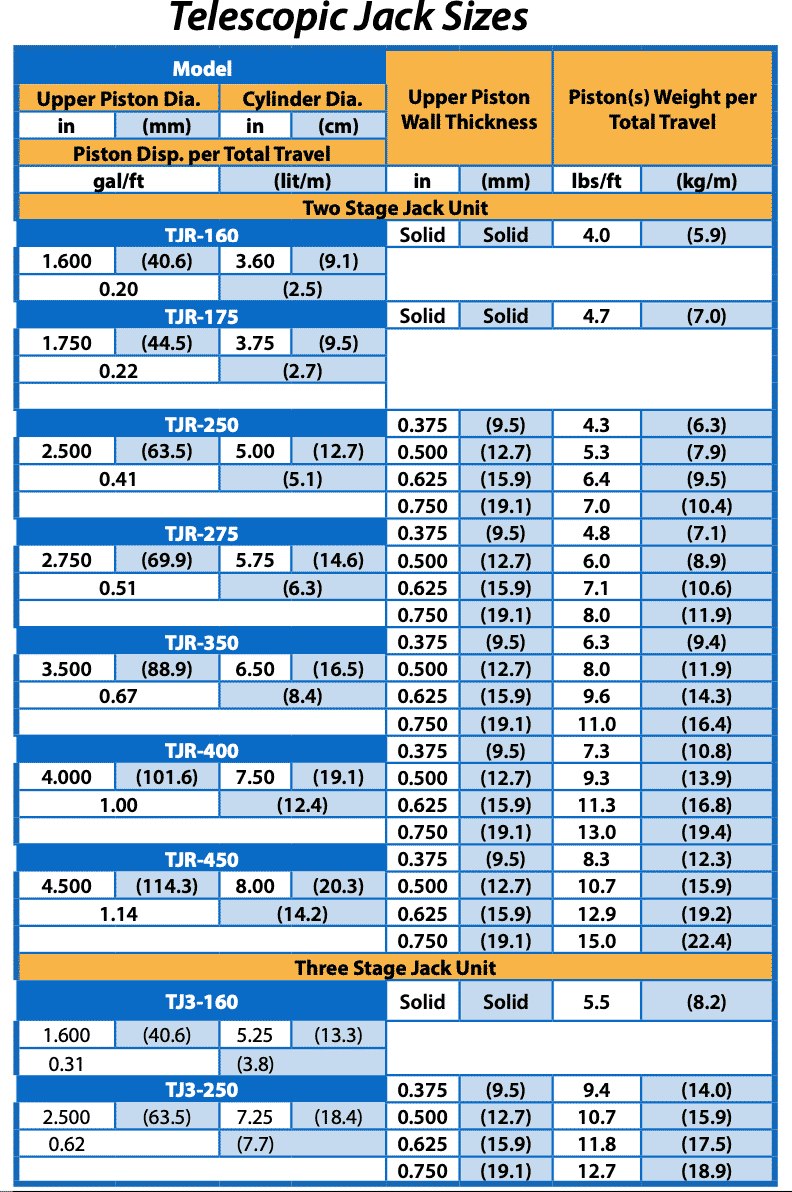

EECO Telescopic Jack

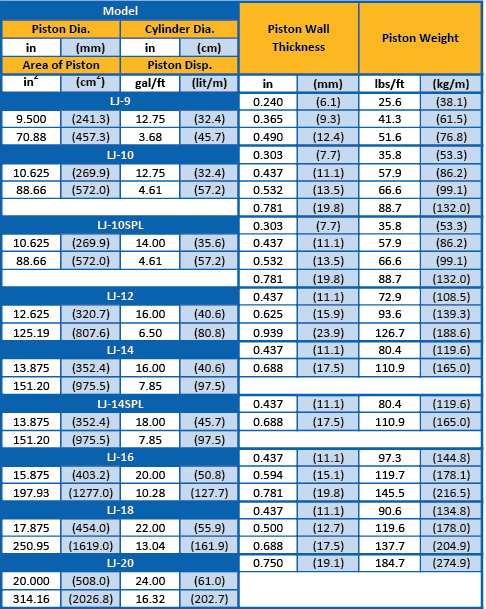

Elevator Equipment Corporation (EECO) has been manufacturing hydraulic elevator equipment since 1946, and is one of the leading suppliers in the industry for elevator jack units, replacement cylinders, and pistons. EECO can provide jack units for any application, from small capacity residential to the largest freight elevators. EECO has over 30 standard size jack units with many piston wall thicknesses available to meet your predetermined specifications or our engineering and sales staff can work with you to determine which EECO Jack Unit is right for your application.

Download our Product Brochure.

All EECO jack units are manufactured with precision equipment, experienced production personnel, and a knowledgeable engineering staff to produce a quality product for our customers. The latest CNC equipment and technology is utilized to assure strict adherence to essential dimensions and tolerances. All EECO products are designed and manufactured in accordance with the Safety Code for Elevators and Escalators, ASME A17.1/CSA B44. With years of testing and field study, EECO has designed jack units that are unparalleled in the industry for performance and reliability. The primary objective of Elevator Equipment Corporation is to provide a quality product that consistently meets or exceeds the contractual demands and expectations of our customers.

Quality Assurance

Quality Control is an essential and integral part of our manufacturing process. Every phase of production is monitored and checked to assure that each jack unit is built and assembled in accordance with engineering and customer specifications to meet the quality standards required by Elevator Equipment Corporation. From the initial process of material as it comes in the door, to the final process of placing the product on the truck, you can be assured that our high quality standards are met and that the finished product meets your requirements.

Jack, Piston, or Cylinder Replacement

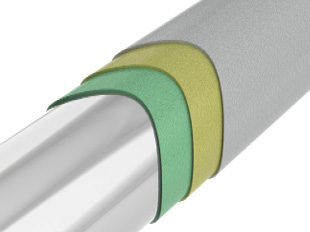

EECO specializes in Jack Unit Replacement. We can provide an exact replacement, either piston, cylinder or complete jack units, regardless of original make or manufacturer. Before 1972 many companies installed hydraulic elevators with flat bottom in-ground jack units, many without any corrosion protection at all. Failures on these older designs may cause rupturing of the cylinder and uncontrolled decent of the elevator. Today's ASME A17.1/CSA B44, Section 8.6.5.8 requires single bottom jack units (cylinders) to be replaced with double bottom cylinders.

Delivery Times

It is our goal to deliver a jack unit when needed. If rush delivery is required, EECO can manufacture and ship certain jack units in as little as 48 hours. Contact EECO for current lead times.

Green Compatible

All EECO Products are “Green Compatible” as a standard when used with biodegradable (vegetable) oils that do not contain a high acidic property.

Material & Welding

All steel parts are fabricated and machined from high strength carbon steel. All welding is in accordance with the requirements of Part 8 of ASME A17.1/CSA B44. EECO welding is AWS and our Richmond facility is CWB certified.

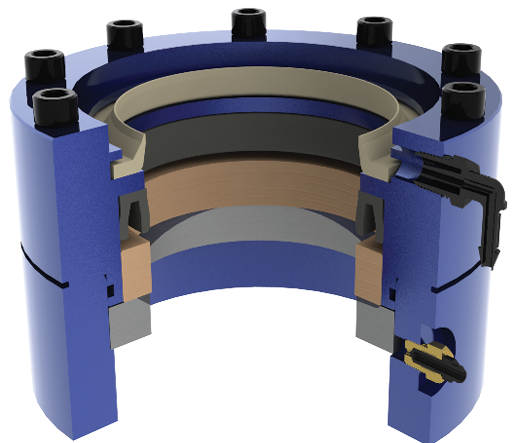

The upper end of the piston is fitted with a drilled and tapped plate, to receive a standard bolt for attachment to the platen plate (special mounting arrangements can be provided). The bottom of the piston is closed with a steel plate and is fitted with a stop ring to prevent the piston from leaving the cylinder. The piston is ground and polished to a surface finish of 15 to 20 µin (.38 to .50 μm). Allowable variation in diameter after polishing is ± .015" (.381 mm).

The upper end of the piston is fitted with a drilled and tapped plate, to receive a standard bolt for attachment to the platen plate (special mounting arrangements can be provided). The bottom of the piston is closed with a steel plate and is fitted with a stop ring to prevent the piston from leaving the cylinder. The piston is ground and polished to a surface finish of 15 to 20 µin (.38 to .50 μm). Allowable variation in diameter after polishing is ± .015" (.381 mm).

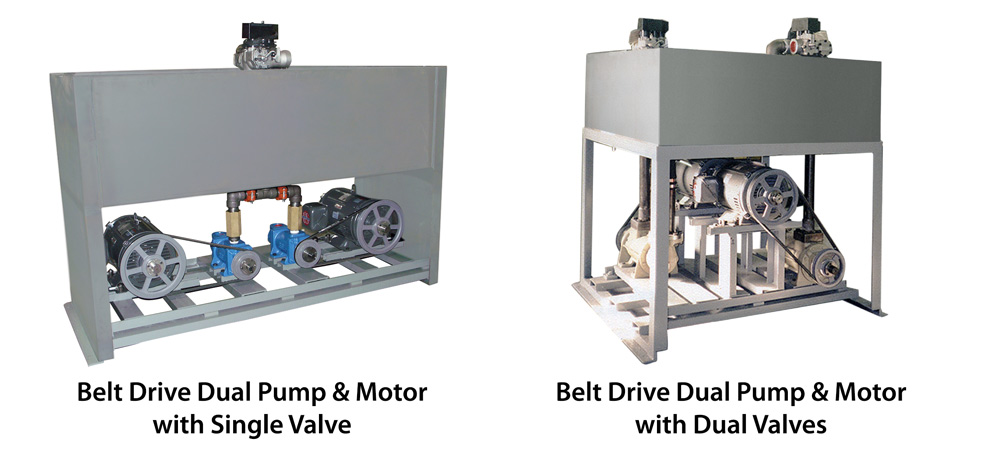

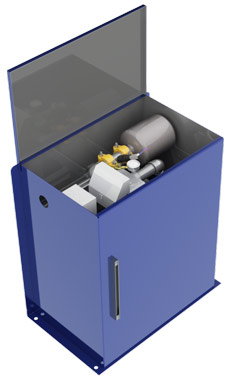

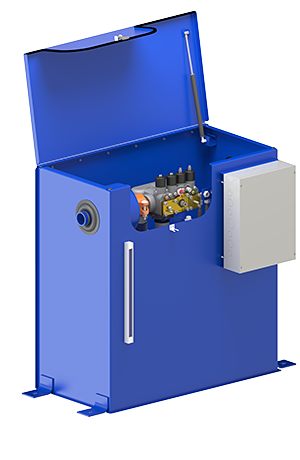

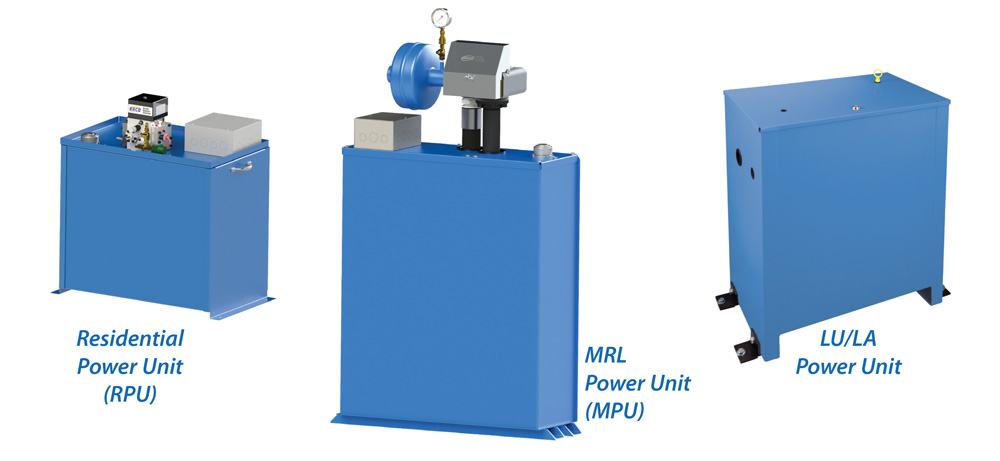

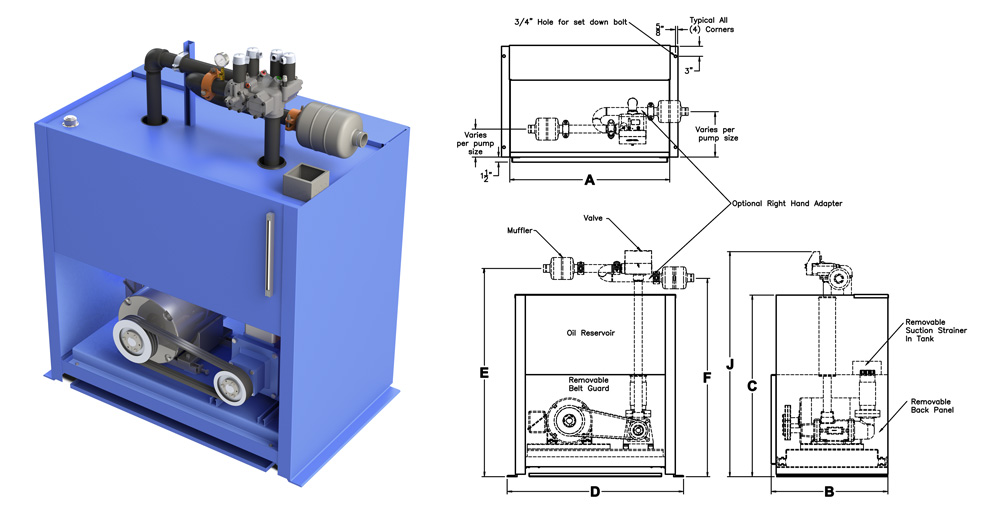

EECO manufactures hydraulic elevator power units with precision equipment, skilled and experienced production personnel, and a knowledgeable engineering staff to comply with the exacting standards required to produce a quality product. The latest CNC equipment and technology is utilized to assure strict adherence to essential dimensions and tolerances. All EECO products are designed and manufactured in accordance with the Safety Code for Elevators and Escalators, ASME A17.1/CSA B44. With years of testing and field study, EECO has designed submersible and belt drive power units that are unequaled in the industry for performance and reliability. The primary objective of Elevator Equipment Corporation is to provide a quality product that consistently meets or exceeds the contractual demands and expectations of our customers.

EECO manufactures hydraulic elevator power units with precision equipment, skilled and experienced production personnel, and a knowledgeable engineering staff to comply with the exacting standards required to produce a quality product. The latest CNC equipment and technology is utilized to assure strict adherence to essential dimensions and tolerances. All EECO products are designed and manufactured in accordance with the Safety Code for Elevators and Escalators, ASME A17.1/CSA B44. With years of testing and field study, EECO has designed submersible and belt drive power units that are unequaled in the industry for performance and reliability. The primary objective of Elevator Equipment Corporation is to provide a quality product that consistently meets or exceeds the contractual demands and expectations of our customers. EECO can provide units for installation in hazardous or humid environments using moisture resistant or explosion proof components. Explosion Proof Valves have a NEMA 7 rating. Contact EECO for more information.

EECO can provide units for installation in hazardous or humid environments using moisture resistant or explosion proof components. Explosion Proof Valves have a NEMA 7 rating. Contact EECO for more information.

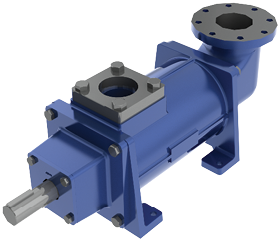

Submersible pumps are positive displacement, low slip, three screw design, and are directly connected to the motor.

Submersible pumps are positive displacement, low slip, three screw design, and are directly connected to the motor.

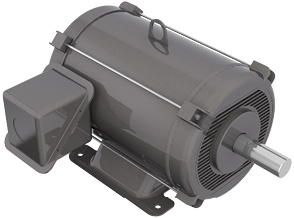

Submersible motors are designed to operate submerged in oil and are rated at 80 starts/hr or 120 starts/hr. 3-Phase motors are 3400 rpm and include leads for Across-the-Line, Wye-Delta, or Solid State starting. Single-Phase motors are 1750 rpm or 3400 rpm for 10hp (7.4kW) and include the starting capacitors for Across-the-Line starting.

Submersible motors are designed to operate submerged in oil and are rated at 80 starts/hr or 120 starts/hr. 3-Phase motors are 3400 rpm and include leads for Across-the-Line, Wye-Delta, or Solid State starting. Single-Phase motors are 1750 rpm or 3400 rpm for 10hp (7.4kW) and include the starting capacitors for Across-the-Line starting.

All power units include an EECO control valve as standard. A Constant Down Speed control valve can be furnished as an option. All units are supplied with 1/8” brass shut off valve and male quick-disconnect fittings.

All power units include an EECO control valve as standard. A Constant Down Speed control valve can be furnished as an option. All units are supplied with 1/8” brass shut off valve and male quick-disconnect fittings.

The Oil Level Liquid Gauge is made of corrosion and rust resistant milled aluminum. The end pieces are permanently secured through a staking process. Fluid enters through the cross hole in the hollow lower bolt and is communicated back into the tank through the cross hole in the hollow top bolt.

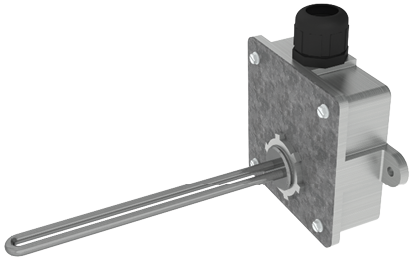

The Oil Level Liquid Gauge is made of corrosion and rust resistant milled aluminum. The end pieces are permanently secured through a staking process. Fluid enters through the cross hole in the hollow lower bolt and is communicated back into the tank through the cross hole in the hollow top bolt. The Thermal Switch Assembly (TSW-1) is required to be installed on all Hydraulic Power Units, per ASME A17.1/CSA B44 3.26.6.5, to prevent the liquid temperature from rising above its maximum operating temperature. These switches are factory preset at a temperature setting of 145º F (63º C).

The Thermal Switch Assembly (TSW-1) is required to be installed on all Hydraulic Power Units, per ASME A17.1/CSA B44 3.26.6.5, to prevent the liquid temperature from rising above its maximum operating temperature. These switches are factory preset at a temperature setting of 145º F (63º C).

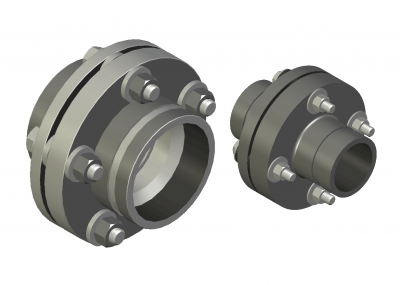

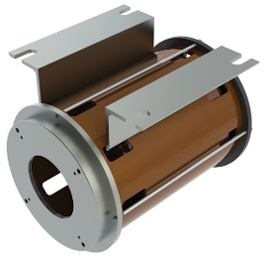

The Hydraulic Dampener (EHD) is extremely effective in suppressing the sound and pulsation present in hydraulic elevator systems. The EHD has a minimum burst pressure of 6000 psi with an ASME A17.1/CSA B44 allowable working pressure of 1200 psi.

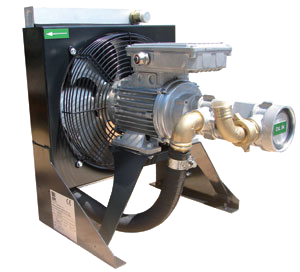

The Hydraulic Dampener (EHD) is extremely effective in suppressing the sound and pulsation present in hydraulic elevator systems. The EHD has a minimum burst pressure of 6000 psi with an ASME A17.1/CSA B44 allowable working pressure of 1200 psi. The Oil Cooler (OC) is extremely efficient in cooling the oil in the hydraulic elevator machine room in which it is installed. The heart of the unit consists of a triple screw pump which is highly reliable and quiet.

The Oil Cooler (OC) is extremely efficient in cooling the oil in the hydraulic elevator machine room in which it is installed. The heart of the unit consists of a triple screw pump which is highly reliable and quiet. The Tank Heater (TH) is simple to install and operate. Designed to keep your hydraulic oil at the optimum operating temperature in cooler environments to provide optimum operation of your hydraulic elevator system. Pre-Set 110° F Thermostat, 120 Volt AC, 250 Watts, 2.1 Amps, Oil-Tight Fittings included.

The Tank Heater (TH) is simple to install and operate. Designed to keep your hydraulic oil at the optimum operating temperature in cooler environments to provide optimum operation of your hydraulic elevator system. Pre-Set 110° F Thermostat, 120 Volt AC, 250 Watts, 2.1 Amps, Oil-Tight Fittings included. The Shut Off Valve (SOV) is used to isolated one section of the system from another. All Shut Off Valves are constructed of ductile iron bodies and use a stainless steel ball. A locking device is standard on all sizes.

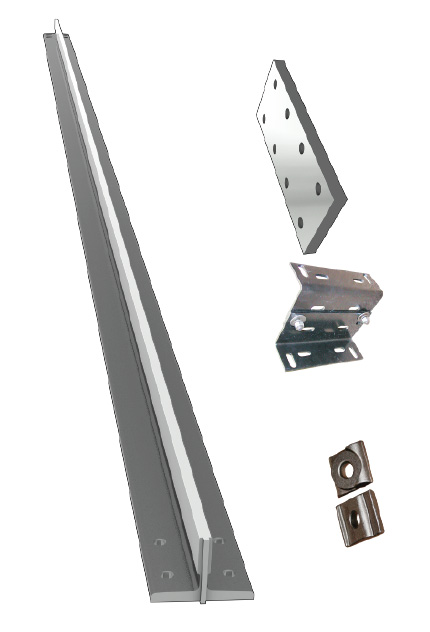

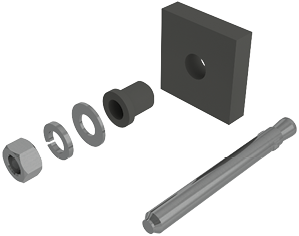

The Shut Off Valve (SOV) is used to isolated one section of the system from another. All Shut Off Valves are constructed of ductile iron bodies and use a stainless steel ball. A locking device is standard on all sizes. The EECO’s Load Weighing Kit (LWK) is an addition to a new or existing Power Unit to prevent the elevator from being overloaded. The switch can be wired into the controller, if the provision is available, through either a normally open or normally closed contact.

The EECO’s Load Weighing Kit (LWK) is an addition to a new or existing Power Unit to prevent the elevator from being overloaded. The switch can be wired into the controller, if the provision is available, through either a normally open or normally closed contact.  The Oil Level Sight Glass for hydraulic elevator power units is used to visually inspect the oil level in the tank. It is available in 1” Diameter with NPT threads.

The Oil Level Sight Glass for hydraulic elevator power units is used to visually inspect the oil level in the tank. It is available in 1” Diameter with NPT threads. The Valve Return Filter (VRF) is a passive oil filtration system attached to the tank return port of the valve. The VRF allows you to easily comply with the ASME A17.1/CSA B44 Rule 8.6.5.1.1 by capturing particles 5 microns in size and larger preventing the buildup of debris within the tank making it easier to clean.

The Valve Return Filter (VRF) is a passive oil filtration system attached to the tank return port of the valve. The VRF allows you to easily comply with the ASME A17.1/CSA B44 Rule 8.6.5.1.1 by capturing particles 5 microns in size and larger preventing the buildup of debris within the tank making it easier to clean. A Float Level Switch (LOS) is used to detect the oil level in a reservoir. The 1-3/16” diameter float helps to limit surges that might occur. The switch is UL recognized and CSA listed for a maximum of 3 amps @ 250 VAC with a SPST.

A Float Level Switch (LOS) is used to detect the oil level in a reservoir. The 1-3/16” diameter float helps to limit surges that might occur. The switch is UL recognized and CSA listed for a maximum of 3 amps @ 250 VAC with a SPST.  A thermostat that is field adjustable by a fine adjustment trim screw which can activate a viscosity control system. The thrermostat is UL and CSA recognized for a maximum of 1500 watts at 230 volts AC with a single contact. The unit has a heat sensitive base plate which can be mounted directly to the outside of a hydraulic tank or by an aluminum “L” bracket with little loss of sensitivity.

A thermostat that is field adjustable by a fine adjustment trim screw which can activate a viscosity control system. The thrermostat is UL and CSA recognized for a maximum of 1500 watts at 230 volts AC with a single contact. The unit has a heat sensitive base plate which can be mounted directly to the outside of a hydraulic tank or by an aluminum “L” bracket with little loss of sensitivity. The EECO Carbon Desiccant Breather (ECDB) is provided as a contamination control breather technology to reduce particulate, moisture contamination, and hydraulic oil odors by moisture absorption. These are supplied as Replacement Desiccant/Filter Cartridges for ease of service and fully disposable.

The EECO Carbon Desiccant Breather (ECDB) is provided as a contamination control breather technology to reduce particulate, moisture contamination, and hydraulic oil odors by moisture absorption. These are supplied as Replacement Desiccant/Filter Cartridges for ease of service and fully disposable.